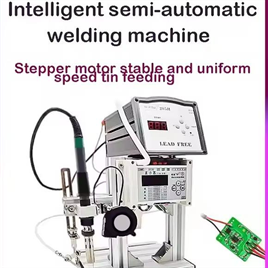

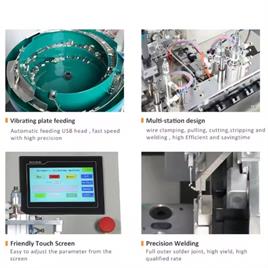

Automatic Soldering Machine

Automatic Soldering Machine

Brand:

Others

Price ₹

12,39,790.00

₹12,41,790.00

| General Details: | |

| model | IE-ST380C / Automatic Soldering Machine |

| Heater Power | 100ºC~500ºC |

| Power Supply | 220V AC/50HZ |

| Solder Capacity | (Unlimited) |

| Heat Up Time | 0~40ºC, humidity 20%~95% |

| Others: | |

| Country of Origin | Made in India |

| Available | In Stock |

| Business Type | Manufacturer, Supplier |

| Condition | Brand New |

| I Deal In | New Only |

| Minimum Quantity Order | 1 Unit |

Single Side Soldering Robot for FPC Sas Cable Slim Wire Cable,IE-MC301

Brand:

Others

Price ₹

9,54,991.00

| General Details: | |

| model | IE-MC301 |

| Material | Soldering |

| Heater Power | 0-660 ºC |

| Power Supply | 220V, AC |

| Solder Capacity | 400 - 600PCS / H (by product) |

| Heat Up Time | 1-2 sec / segment |

| Others: | |

| Country of Origin | Made in India |

| I Deal In | New Only |

| Minimum Quantity Order | 1 Unit |

| Condition | Brand new |

| Available | In Stock |

| Colour | Silver |

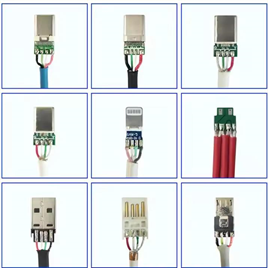

HDMI Cable Soldering Machine,IE-HDMI

Brand:

Others

Price ₹

2,58,358.00

| General Details: | |

| model | IE-HDMI |

| Heater Power | 10-60ºC,40%~90% |

| Power Supply | 220V AC 50-60HZ |

| Solder Capacity | 1000~1300pcs/H |

| Heat Up Time | 2-3sec. |

| Others: | |

| Available | In Stock |

| Business Type | Manufacturer, Supplier |

| Condition | Brand New |

| Features | Automatic welding for HDMI, USB 3.0, DP, RGB, DVI, SATA |

| I Deal In | New Only |

| Minimum Quantity Order | 1 Unit |

| Power Output | 1.8 KW |

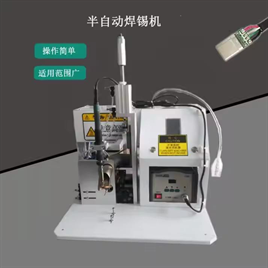

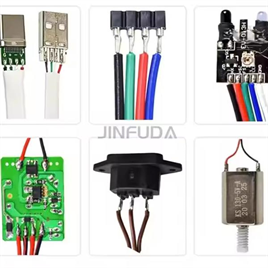

Semi Automatic USB Data Wire Cable Soldering Machine

Brand:

Others

Price ₹

90,000.00

| General Details: | |

| model | Semi Automatic USB Data Wire Cable Soldering Machine |

| Others: | |

| Additional Features | Auto tin feeding, adjustable soldering time, CE certified |

| Applications | USB A, Micro USB, Type-C, iPhone connectors, data cables |

| Business Type | Manufacturer, Supplier |

| Condition | Brand New |

| Control System | PLC with digital display, foot pedal operation |

| I Deal In | New Only |

| Power Consumption | 150-800W |

Semi-automatic Soldering Machine, 15v/3A for Aux, Dc, Usb, Led Lights, Power Plug Switch Spot Welding Machine

Brand:

Others

Price ₹

1,20,000.00

| General Details: | |

| model | Semi-automatic Soldering Machine, 15v/3A for Aux, Dc, Usb, Led Lights, Power Plug Switch Spot Welding Machine |

| Others: | |

| Minimum Quantity Order | 1 Unit |

| Applications | Auxiliary cables, DC jacks, USB connectors |

| Automatic grade | Semi-automatic |

| Business Type | Manufacturer, Supplier |

| Condition | Brand New |

| I Deal In | New Only |

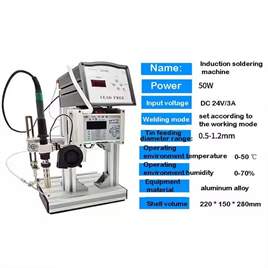

Semi Automatic USB Data Wire Cable Soldering Machines

Brand:

Others

Price ₹

85,000.00

₹1,30,000.00

| General Details: | |

| model | IE-200HX |

| Power Supply | AC 110/220V 50/60HZ |

| Others: | |

| External machine size (L*W*H) | 40*35*40CM |

| Air pressure | 0.5-0.8Mpa |

| Driver mode | Pneumatic/electric |

| Model | IE-200HX |

| Power | 200W |

| Power supply | AC 110/220V 50/60HZ |

| Soldering time& tin feeder | Adjustable |

| Soldering wire | 0.4-2.0mm |

| Temperature accuracy | +/-2? |

| Temperature range | 50-550? |

| Weight | 15kG |

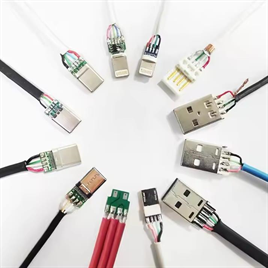

Automatic USB/C/Micro/I-Phone wire connector soldering data cable making machine

Brand:

Others

Price ₹

4,50,000.00

| General Details: | |

| model | IE-06 |

| Power Supply | 220V |

| Solder Capacity | 1200-1500pcs/h |

| Others: | |

| Inner stripping length | 2-10mm |

| Air source pressure | 0.5-0.8MPA |

| Drive Mode | Pneumatic |

| Temperature Control Mode | Thermostatic (Zones) |

| Machine Dimensions(L*W*H) | 1.15x0.80x1.15M |

| Machine Weight | 160KG |

| Working Voltage | AC220V |

| Working Efficiency | 600~1100Pcs/H |

| condition | New |

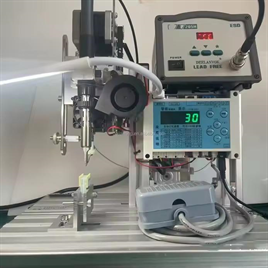

Single Robotic Arm Soldering Machine

Brand:

Others

Price ₹

4,30,000.00

₹12,39,790.00

| General Details: | |

| model | Single Robotic Arm Soldering Machine |

| Others: | |

| Operate speed (X/Y/Z/R) | X/Y/Z:600mm/s |

| Repeat Accuracy | ±0.02mm |

| size | (W*D*H)620*520*820 |

| Technical Index | Tech-Parameters |

| trace (X*Y*Z*R)mm | 500*300*100*360° |

| Voltage | 220V AC/50HZ |

| weight | 55kg |

USB Stripping and Soldering Machine

Brand:

Others

Price ₹

4,00,000.00

| General Details: | |

| model | USB Stripping and Soldering Machine |

| Material | Plastic |

| Others: | |

| rated duty cycle | 90% |

| dimensions | 1100*600*1100 |

| usage | Welding terminal |

| warranty | 1 Year |

| weight (kg) | 110 |

| Product name | Automatic Usb Cable Soldering Machine |

| Solder terminal type | Apple hea, USB A/M, USB A/F, Micro, Type-c |

| Capacity | 1200-1500 pieces/h |

| Working pressure | 0.4-0.8MPA |

| Voltage | AC220V |

| Power | 200W |

| Size | 1100*600*1100mm |

| Weight | 110kg |

| After-Sales Service | 1 year |

HDMI Cable Soldering Machine

Brand:

Others

Price ₹

3,50,000.00

| General Details: | |

| model | HDMI Cable Soldering Machine |

| Heater Power | 1.8KW |

| Power Supply | 220V |

| Solder Capacity | customized |

| Others: | |

| Air Pressure | 2-4kg |

| Machine Dimensions(L*W*H) | 45*32*25cm |

| Technical Index | Tech-Parameters |

| Weight | 20KG |

| Working efficiency | 1000~1300pcs/H |

| Working environment | 10-60?,40%~90% |

| Working Voltage | 220V AC 50-60HZ |

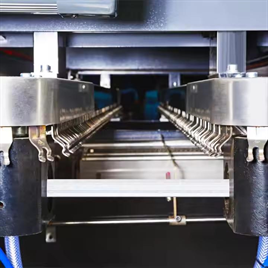

Wave Soldering Machine | PCB soldering Machine | Indoe

Brand:

Others

Price ₹

7,85,000.00

| General Details: | |

| model | IE-250M |

| Material | SS |

| Others: | |

| Automation Grade | Fully Automatic |

| Business Type | Manufacturer, Supplier |

| Condition | Brand New |

| Country Of Origin | Made in India |

| Fluxing System | Foam fluxer |

| I Deal In | New Only |

| Minimum Quantity Order | 1 Unit |

if you are interested, please fill the below details: